I start by cutting rings from brass tubing - in 1/48 scale 9/32 tube cut to 1/16 inch thick. I use a cut off machine from Harbor Freight Tools which is similar to a more expensive unit sold by Micro Mark.

Next, deburr the rings and then solder them to a sheet of .005" brass. Cut each porthole from the sheet and trim so that the thin back is flush with the outer rim of the port

Plot the location of each porthole from plans and pictures (be sure to check both!), and then drill small location hole. Often, a line of masking or other tape is useful to see if everything is even prior to drilling

I have had good sucess using a brad point bit to make the hole.

Drill very carefully and with the slowest speed thru fiberglass to a depth just a little over 1/16 inch deep

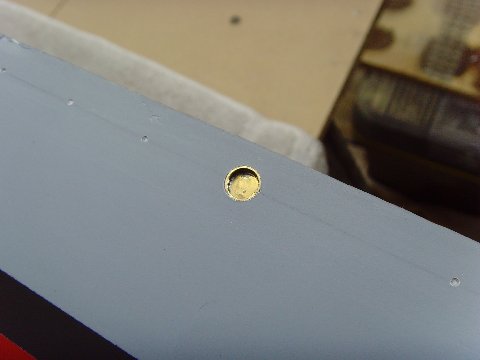

Put a dab of epoxy in hole, and then insert porthole in the hole

Try to keep porthole flush with the hull

Once the epoxy is dry, sand the area around port, prime and paint. If desired you can paint the back of the port a dark color, and install a sheet of clear plastic over it to simulate the glass.

Joe Hanacheck is the owner of West Coast Warships, a supplier of 1/48 scale Warship Hulls.

Back to Construction Articles

69

Version 1.0 10/08